Europe's online source of news, data & analysis for professionals involved in packaged media and new delivery technologies

How the SteelBook was born

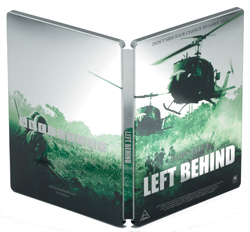

SteelBook is a new packaging for high profile music, video and games releases. The pack consists of a metal exterior and an inner core of plastic and has the same dimensions as a standard DVD style case. This new product, which offers a full range of design possibilities including printing on both the exterior and interior, is something of a triumph of industrial design. This is the story of its making.

The single disc version is featured with Scanavo’s patented disc rosette securing product safely. The double disc version features Pozzoli’s patented Overlap allowing both discs to be visible simultaneously

In 2002, Glud & Marstrand A/S, Scandinavia’s largest manufacturer of metal packaging, decided to target the development of new metal products for the media industry. This was in order to offer the exclusive feel and shelf appearance of metal to an industry that has mainly based its efforts on plastic, and which has been seeking an alternative for a considerable amount of time.

Torsten Brix, Director Group R&D at G&M says: “In the beginning we were very surprised that nobody had picked up on the challenge and developed a serious metallic alternative for the media industry, which suffers from packaging, the quality of which rarely matches up to the digital products. There is a striking disparity between an expensive, quality movie or game and cheap packaging made from plastic or cardboard.

“When we looked for examples of metal packaging being used in the media industry, we found only scarce and hapless attempts at adapting known technology from traditional food packaging. Attempts that never really got past the ‘gimmick’ stage or offered a real alternative.

“We quickly realised that if metal packaging was to offer any real value and novelty, visual and tactile qualities combined with automated production were absolute demands.

“Our first analyses of the market provided us with a clear image of an industry that was characterised by two main demands: cheap standard plastic packaging and an apparent heavy demand for differentiation and more exclusive packaging. These demands were and are satisfied by means of a broad offering of various cardboard solutions that lose their exclusive aura after being used only a few times.

“The few serious attempts made at developing a dedicated CD/DVD metal box lacked metal’s inherent aesthetic qualities and possibilities. Half-baked solutions, such as a simple thin plastic hinged back, spoils the general impression again and again.

“Eventually, we realised why nobody had done it before: it was a challenge of immense dimensions to achieve both the aesthetic qualities and the ability to automate production. The seemingly simple task took on the dimensions of a Gordian knot, which was only solved as a result of a close, organic co-operation between our engineers and designers.

Our industrial designers, Mazyar Abolfazlian and Niels Toft Jørgensen, spent almost a year with our chief engineer Esad Zubcevic and his team solving the automation problem. They overcame all the difficulties while retaining the visual expression of a ‘full metal jacket’”.

When G&M started developing the all-metal box, the company knew that logistics would be a decisive factor. They employed Jan Bjerregaard, who has a background as plant manager in the media packaging and production industry, to be in charge of the SteelBook project.

Jan Bjerregaard, Manager Media Packaging at Glud & Marstrand says: “With my background and experience in the media packaging industry I knew how important the logistical process is for content owners – regardless of whether we are talking about movies, music, games or software.

“The automation demands are crucial, partly with respect to the time relationship between the release of the discs’ digital content and the marketing plans, partly with respect to the security aspects related to letting the discs being handled by too many people over too long time.

“Counterfeiting is a constantly growing problem currently facing the industry, and exactly the counterfeiting aspect struck me as a unique opportunity for SteelBook. The fact that packaging such as the SteelBook takes an entirely different route through the logistics chain makes it not only harder to counterfeit a new title, but it also takes much longer to do so. This is exactly the period that is the commercially most critical and sensitive for any new release.”

Answering the question of whether G&M had any reservations utilising so many innovation resources on the media packaging industry, which is known for so many cases of IPR infringements, Torsten Brix reponds: “We feel confident that the media industry, which suffers so severely from counterfeiting and product piracy, will appreciate the fact that a major player in the packaging industry has invested so many resources into developing a totally new type of packaging like SteelBook, which we are convinced will support their business goals substantially.

“Nevertheless, we are of course fully aware that although we have taken all possible measures to protect our investment IPR-wise, all businesses have their own parasites who will feel tempted to take the short cut and steal from others who have the courage and the guts to put their own money into risky investments in innovation.

“But again, all the appreciation from the media industry that we have already received, gives us reason to believe, that although some will feel tempted by a cheaper business proposal everyone will end up focusing on what is the long term common interest of us all.

At G&M we are already heavily investing expected future profits from SteelBook into developing both overt and covert features that will help the media industry efficiently to fight against theft, piracy and counterfeiting, and thus support their endeavours to protect their investments.”

During the entire development process a central demand for Glud & Marstrand’s team of developers was that the new packaging solution could be integrated into the existing production facilities at the CD/DVD producers.

Otherwise, such an aesthetic package would never find its feet on the media market. Before the final, unique SteelBook saw the light of day a substantial number of problems and challenges needed to be solved and overcome.

It is clear from the earlier attempts to create a metal packaging solution for the media industry that it is not an easy task. Even after countless attempts no one has succeeded in creating a metal packaging solution that can be automated, even though it would have clear and self-evident advantages. It quickly became clear that the demands from the industry’s automated packing machines were practically incompatible with the limits on producing metal packaging, both with respect to functionality and production processes.

G&M had made contact with a very large software producer for whom the development team attempted to create a dedicated packaging solution. The design ambition was to create packaging for the more advanced software products, which were to be produced in such small numbers that the automation demand was revoked.

For a while this opened the opportunity to work more freely on the concepts, but the joy was short-lived. Soon it became clear that the software producer wanted packaging for mass-produced products. The developers were forced back to square one and the great challenge.

Later, the development team realised that the material they were working on was so thin that the joins would be razor sharp with a substantial risk of injury to users.

In fact, every exposed metal edge contributes a great security risk for the consumers. This is one of the central reasons for the high degree of finishing on all the SteelBook’s metal parts.

An earlier version of the SteelBook also made it clear that it had an unacceptable mechanical weakness at the opening grip. Where the metal and plastic parts of the grip meet, a weakness in the metal will invariably occur, which may result in a plastic deformation.

The development team knew that the best solution, both mechanically and aesthetically, would be to shape the grip in metal. However, such a solution placed such demands on the shaping process that it was initially rejected.

As the final SteelBook design shows, Glud & Marstrand’s developers succeeded in reaching the exact production process that can handle such intense and critical treatment of the metal shells.

The industrial designers responsible for the SteelBook design – Mazyar Abolfazlian and Niels Toft Jørgensen – have come up with a revolutionary design that creates a completely new range of opportunities for the media industry.

The designers take up the story: “Our goal was to fill an empty space in the media market by raising the ‘perceived value’ – the imaginary value connected to purchasing – of a product. Games, software, movies and music are often expensive but the actual products are sold in plastic packaging that rarely looks good.

“We wanted to develop a container that makes the customer feel like he is getting more for his money. This is why we have focused on how the product feels in the hand, the sound and the sensation when it is opened. At the same time it had to look good on the shelf, in the bookcase or on the table.

“When the general goals had been established they were followed by a number of brainstorming meetings. The meetings resulted in numerous sketches and computer drawings, which all revolved around digital storage media. We selected a few concepts, which we then split between us, went home and continued working on them alone. When we met up again we made a list of what was good or bad about each idea – and what was possible for us to produce.

“The entire development process took place in a close, organic co-operative effort, where we constantly investigated new design ideas with Glud & Marstrand’s experienced engineers, and checked if they could hold water. More often than not they didn’t. For example, we experimented with folding the metal, which opened up for a wide variety of design options. This resulted in a flow of design ideas, which were produced in cooperation with both internal and external partners.

“In early 2003 it was clear that the SteelBook would be made out of a combination of plastic and metal. Metal on the outside to give it the exclusive look and feel that is one of metal’s unique qualities. Plastic on the inside to provide the SteelBook with the relatively complex mechanical features: hinge, disc fixture, booklet fixture and more.

“All that remained was to make all the ends meet:

- A complete metallic outer surface

- A fully decorated back with the ability to open 240 degrees

- Compliance with existing DVD box outer dimensions with out restricting internal space

- Opening geometry that emulated standard DVD packaging

- The opening grip needed to be adapted to existing packing machinery

- Full visibility of internal decoration of the metal case through a transparent inner plastic part

“In June 2003 we made the final design breakthrough and stood with a complete SteelBook concept. Now we knew that the front and back of the SteelBook had to be deep drawn and then shaped, and that the geometry of the plastic on the inside was more or less determined.

Apart from the opening grips, which consist of plastic that has been extended through the inner plastic parts we had achieved a fully metallic expression without limiting the opening geometry so much that automation was impossible. What remained was work on the design within the framework that had been a result of the mechanical construction.

Soon it became clear that the SteelBook had an unacceptable mechanical weakness at the exact same place as we perceived it to have its greatest aesthetic weakness: the opening grip.

In the transition from metal to plastic a weakness would invariably develop in the metal that would make it susceptible to deformation as a result of normal use.

We knew that the best solution, both mechanically and aesthetically would be to shape the grip in metal. “However, such a solution demands so much of the shaping process that we initially gave up on it.

The final SteelBook design proves that we have succeeded in developing a production process that can handle such intense and critical manufacturing of the metal shells.

Now the box has been shaped with a smooth rounded curve that enables your fingers to grip and open the box. We took advantage of the metal’s strength and at the same time achieved a completely metallic look”.

A combination of matt and glossy lacquers can be used to create special design effects while embossing remains a unique way to create extra appeal.

Mazyar Abolfazlian holds a master’s degree from the Aarhus School of Architecture (1999). He has worked on projects for Alfa Romeo in Italy and has also designed lighting, furniture, office supplies and fittings. Some of his recent furniture designs have been exhibited at the ICFF in New York in 2004.

Niels Toft Jørgensen took his master’s degree at the Aarhus School of Architecture in 2000. Today Niels works for several large companies, such as Grundfos and Bang & Olufsen, where he is attached to the development department as concept developer. Niels took G&M in as his first customer back in 1997.

Glud & Marstrand A/S is the owner of several intellectual property rights together with other rights to and in SteelBook. The unconditional policy of G&M A/S is to take any appropriate legal action against any possible infringement of our rights.

The company says it feels confident that the media industry, which suffers so severely from counterfeiting and product piracy, will appreciate the fact that a major player in the packaging industry has invested so many resources into developing a totally new type of packaging like SteelBook, which is intended to support their business goals.

“Nevertheless,” says G&M, “we are of course fully aware that although we have taken all possible measures to protect our investment IPR-wise, all businesses have their own parasites who will feel tempted to take the short cut and steal from others who have the courage and the guts to put their own money into risky investments in innovation.”

Appreciation from the media industry that the manufacturer has received “gives us reason to believe that although some will feel tempted by a cheaper business proposal, everyone will end up focusing on what is the long term common interest of us all.”

G&M is already heavily investing expected future profits from SteelBook into developing both overt and covert features that will help the media industry efficiently to fight against theft, piracy and counterfeiting....

On predicting the future

Predicting the future, let alone the future of packaged media, is a perilous exercise, and possibly counter-productive, as the exercise closes doors rather than keep them open, argues JEAN-LUC RENAUD, DVD Intelligence publisher. Consider that: Apple was left nearly for dead 15 years ago. Today, it became the world's most valuable technology company, topping Microsoft.

Le cinéma est une invention sans avenir (the cinema is an invention without any future) famously claimed the Lumière Brothers some 120 years ago. Well. The cinématographe grew into a big business, even bigger in times of economic crisis when people have little money to spend on any other business.

The advent of radio, then television, was to kill the cinema. With a plethora of digital TV channels, a huge DVD market, a wealth of online delivery options, a massive counterfeit underworld and illegal downloading on a large scale, cinema box office last year broke records!

The telephone was said to have no future when it came about. Today, 5 billion handsets are in use worldwide. People prioritize mobile phones over drinking water in many Third World countries.

No-one predicted the arrival of the iPod only one year before it broke loose in an unsuspecting market. Even fewer predicted it was going to revolutionise the economics of music distribution. Likewise, no-one saw the iPhone coming and even fewer forecast the birth of the developers' industry it ignited. And it changed the concept of mobile phone.

Make no mistake, the iPad will have a profound impact on the publishing world. It will bring new players, and smaller, perhaps more creative content creators.

And who predicted the revival of vinyl?

(click to continue)... Read More...